Felt Roof Underlayment: Classic Protection for Reliable Roofing Performance

Felt roof underlayment remains one of the most trusted and widely used materials in the roofing industry. Known for its durability, affordability, and reliable performance, felt underlayment has traditionally been the backbone of residential shingle roofs. Even with modern synthetic options on the market, many builders, contractors, and homeowners still rely on felt to provide a dependable moisture barrier and a protective layer between the roof deck and the shingles above it.

This underlayment is made from natural or synthetic fibers that are saturated with asphalt, creating a water-resistant material that enhances the strength of the roofing system. Its purpose is simple but essential—to offer an added layer of defense against water, wind, and temperature changes. Felt roof underlayment helps preserve the roof deck, improve shingle adhesion, and prevent moisture from seeping into the home.

What Is Felt Roof Underlayment?

Felt roof underlayment, commonly known as “roofing felt” or “tar paper,” is an asphalt-saturated material installed under shingles to protect the roof deck. It is available in two primary thicknesses: 15-pound felt and 30-pound felt. The 30-pound variant is thicker, stronger, and offers better resistance to tears and moisture.

The material is designed to serve as the roof’s secondary line of defense. If shingles become damaged, blow off, or lift during storms, the felt underlayment continues to provide temporary protection by slowing down water penetration. This makes it a valuable and effective barrier in many roofing systems.

How Felt Roof Underlayment Works

The primary function of felt underlayment is to prevent moisture from reaching the roof deck. By absorbing small amounts of water and slowing its movement, the felt layer minimizes the risk of wood rot, mold, and roof deterioration. In addition to moisture control, felt underlayment also helps regulate heat. It adds a layer of insulation that reduces the transfer of heat from the shingles to the attic space.

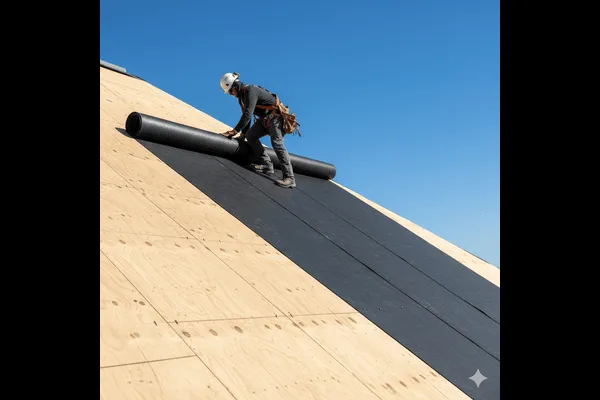

During installation, felt rolls are laid horizontally across the roof deck with overlapping edges to prevent gaps. This overlapping structure ensures that water flows downward without slipping between layers. Once shingles are installed on top, the underlayment becomes an additional protective boundary that improves the roof’s overall durability and longevity.

Benefits of Felt Roof Underlayment

Reliable Moisture Protection

Felt underlayment absorbs moisture and prevents water droplets from reaching the wood deck. This is especially helpful during heavy rainfall or when shingles temporarily fail.

Increased Roof Strength

The added layer creates a more stable surface for shingle installation and helps reduce the chances of wood warping or cracking.

Affordable and Widely Available

Felt underlayment is one of the most cost-effective roofing materials and is available in various grades to match different project needs.

Heat Resistance

Due to its asphalt composition, felt underlayment performs well in high-temperature conditions and adds thermal stability to the roof system.

Compatibility with Shingles

Felt has been used with asphalt shingles for decades, making it a trusted combination for residential roofing.

Installation Process for Felt Roof Underlayment

Installing felt roof underlayment requires proper preparation and alignment to ensure maximum protection. The roof deck must be clean and dry before installation. The felt roll is positioned at the lowest point of the roof and unrolled horizontally across the deck. Each row must overlap the previous one to maintain a continuous barrier.

Fasteners such as roofing nails or staples secure the felt to the deck. Care must be taken to avoid wrinkles or air pockets that could interfere with shingle placement. Valleys, edges, and penetrations require special attention to maintain complete coverage. Once the felt layer is secure, shingles or other roofing materials are installed on top.

Felt Underlayment vs. Synthetic Underlayment

While synthetic underlayments are gaining popularity, felt roofing underlayment remains a reliable choice because of its long history of performance and cost-effectiveness. Felt provides good slip resistance during installation, whereas some synthetic materials can feel slick underfoot. Many contractors still prefer felt for its natural feel and predictable behavior during installation.

Synthetic underlayment offers greater tear resistance and lighter weight, but felt continues to be valued for projects where affordability and tradition play a role. Both materials are effective, and the best choice depends on the specific needs of the roofing project.

Where Felt Underlayment Works Best

Felt roof underlayment performs well in a wide range of roofing applications. It is ideal for:

Standard asphalt shingle roofs

Homes in moderate climates

Roofing projects where budget is a priority

Situations where proven reliability is important

Re-roofing projects

Its versatility and long-standing performance make it suitable for both residential and commercial buildings.

Conclusion

Felt roof underlayment remains an essential part of a durable roofing system. Its ability to protect the roof deck from moisture, provide structural support, and enhance overall roof performance makes it a valuable choice for contractors and homeowners alike. Despite the rise of synthetic alternatives, felt continues to earn trust for its simplicity, affordability, and effective protection.

For high-quality roofing materials, including felt underlayment, contact BCP Inc.

📞 877-540-5678

📧 [email protected]